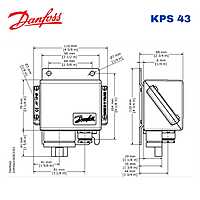

Danfoss KPS 43 High Pressure Switch for Industrial Systems

It is commonly used in compressors, hydraulic systems, power plants, and marine installations requiring robust and reliable pressure protection.

A. Product Overview

The Danfoss KPS 43 is a heavy-duty mechanical pressure switch from the KPS series, engineered for high-pressure applications and systems exposed to pressure pulsations. It is used for alarm, control, and safety shutdown functions in demanding industrial and marine environments.

The switch features a rugged metal enclosure with high ingress protection, making it suitable for outdoor installations and harsh operating conditions. Its design ensures stable switching performance even under vibration, shock, and fluctuating pressure loads.

B. Working Principle

The KPS 43 operates using a diaphragm-based mechanical sensing mechanism. Process pressure acts on the diaphragm capsule, which transfers force to a snap-action SPDT contact system. When the pressure reaches the set value, the contacts change state to trigger alarms, stop equipment, or initiate control logic.

An adjustable differential allows the switch to operate reliably in systems with pressure variations, reducing contact chatter and preventing frequent switching that can lead to premature failure.

C. Key Applications

Industrial air and gas compressors

Hydraulic systems with pressure pulsations

Power generation auxiliary systems

Diesel engine protection circuits

Marine engines and onboard systems

Industrial alarm and safety monitoring

D. Why Industries Use This Product

Industries use the KPS 43 for its reliability, safety contribution, and ability to handle demanding pressure conditions. It helps prevent equipment damage caused by overpressure, enables early fault detection, and supports safe system operation.

In high-pressure or pulsating systems, standard pressure switches may fail due to unstable switching or mechanical fatigue. The KPS 43 is specifically designed to withstand such conditions, reducing false alarms, minimizing downtime, and extending the service life of critical equipment.

E. Suitable Buyers

Compressor and hydraulic OEMs

Power plant and utility engineering teams

Marine system integrators and shipyards

Maintenance and reliability engineers

Procurement teams sourcing standardized pressure switches

It is commonly used for replacement in existing KPS installations and preferred in retrofit projects requiring proven high-pressure performance.

Quick Answers

What is Danfoss KPS 43?

Danfoss KPS 43 is a high-pressure mechanical pressure switch designed for industrial and marine systems with pulsating pressure conditions.

Where is Danfoss KPS 43 used?

It is used in compressors, hydraulic systems, power plants, diesel engines, and marine onboard installations.

Why is Danfoss KPS 43 required in industry?

It protects equipment from overpressure, ensures stable alarm and control functions, and reduces the risk of system failure.

Who typically uses Danfoss KPS 43?

OEMs, system integrators, maintenance teams, power utilities, and industrial procurement professionals.

FAQ Section

Is Danfoss KPS 43 suitable for high-pressure industrial applications?

Yes. The KPS 43 is designed specifically for high-pressure systems and is suitable for applications involving pressure pulsations and demanding operating conditions.

Can KPS 43 be used in hydraulic and compressor systems?

The KPS 43 is widely used in hydraulic circuits and compressor installations where stable pressure monitoring and protection are required.

What is the benefit of adjustable differential in KPS 43?

The adjustable differential helps prevent frequent switching in fluctuating pressure conditions, reducing wear on contacts and improving system stability.

Is KPS 43 commonly used as a replacement pressure switch?

Yes. It is commonly used as a direct replacement in existing KPS series installations, subject to matching application requirements.

Does KPS 43 support system safety and downtime prevention?

By enabling timely alarms or shutdowns during abnormal pressure conditions, the KPS 43 helps protect equipment and reduce unplanned downtime.