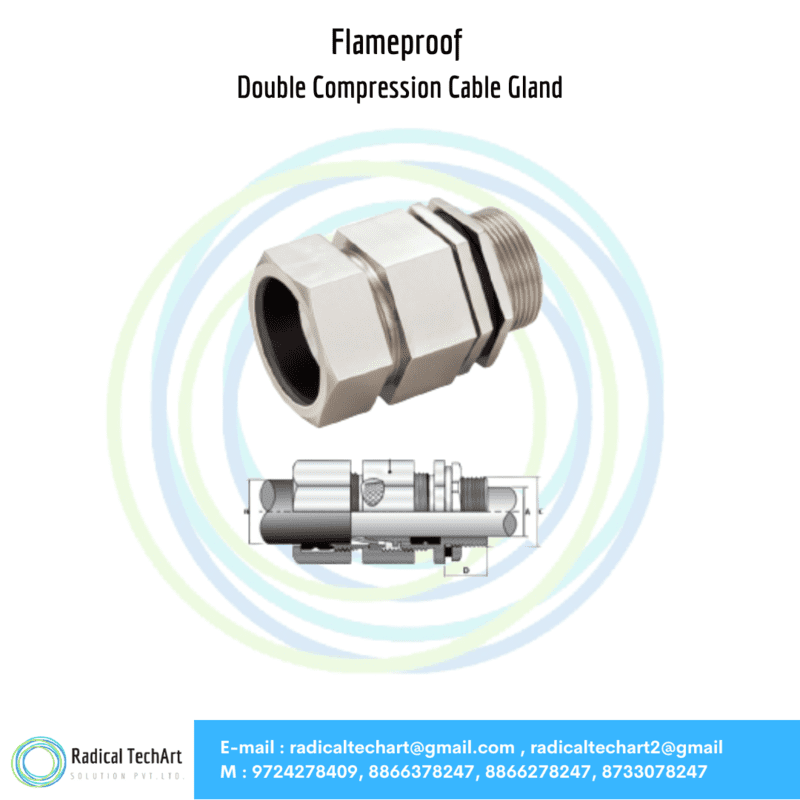

Flameproof Double Compression Cable Gland

Flameproof Double Compression Cable Gland – Brass, IP65, Armoured/Unarmoured

Flameproof and weatherproof double compression cable gland for armored and unarmored cables, providing secure mechanical retention, dual sealing, and electrical continuity in hazardous areas.

This flameproof double compression cable gland is designed for terminating armored and unarmored cables in hazardous and outdoor environments. It offers secure mechanical retention, dual sealing, and electrical continuity, making it suitable for Ex-d/Ex-e equipment where IP65 protection and high reliability are required.

Key Features

Flameproof & Weatherproof: Suitable for hazardous locations with fire or explosion risk; IP65 sealing against dust, moisture, and water jets.

Double Compression Design: Provides independent compression on the inner and outer sheaths of the cable for improved sealing and strain relief.

Mechanical Retention of Armor: Firmly grips cable armor for strong mechanical support and pull-out resistance.

Electrical Continuity: Ensures reliable bonding of cable armor to earth, maintaining continuity through the gland body.

Corrosion-Resistant Construction: Typically manufactured in high-quality brass (optionally nickel-plated) or stainless steel; compatible with PVC shroud for extra protection.

Versatile Thread Options: Available with ET, metric, or NPT threads for compatibility with different equipment entries.

Suitable for Armored & Unarmored Cables: Can be used with single-wire armor, braided armor, or non-armored cables (with appropriate sealing).

Service-Friendly: Detachable armor cone and clamping ring (depending on design) allow easy cable removal and re-termination for maintenance.

Technical Specifications (Table – Generic)

| Specification | Detail |

|---|---|

| Product Type | Flameproof Double Compression Cable Gland |

| Application | Termination of armored/unarmored cables in hazardous areas |

| Construction | Double compression (inner & outer sheath sealing) |

| Material | Brass (optional nickel-plated) / Stainless Steel (on request) |

| Protection Type | Flameproof / Weatherproof (Ex-d / Ex-e compatible – model dependent) |

| IP Rating | Up to IP65 (with proper installation) |

| Cable Types | Armoured and unarmoured power/control cables |

| Mechanical Function | Retention of cable armour and strain relief |

| Electrical Function | Continuity of armour to earth via gland body |

| Thread Types | ET / Metric / NPT (sizes as per model) |

| Finish | Natural brass / Nickel plated / As specified |

| Accessories | PVC shroud, locknut, earth tag (where applicable) |

| Certifications | Suitable for flameproof/hazardous area applications (CIMFR-type) |

Applications

Cable termination in Ex-d / Ex-e junction boxes and enclosures

Chemical, petrochemical and fertilizer plants

Oil and gas refineries and terminals

Paint shops and solvent handling areas

Pharmaceutical and bulk drug units

Outdoor power and control panels in coastal or corrosive atmospheres

What’s in the Box?

1 × Flameproof Double Compression Cable Gland (selected size & thread)

Armour cone and clamping ring (for armoured cable versions)

Entry nut/locknut (if part of standard supply)

PVC shroud (optional—as per ordered configuration)

Installation instruction leaflet or marking label (if supplied by OEM)

FAQ

1) What is the purpose of double compression in this gland?

Double compression provides sealing on both the outer and inner sheaths of the cable. This improves strain relief, sealing, and long-term reliability, especially in hazardous and outdoor environments.

2) Can this gland be used for armored and unarmored cables?

Yes. It is suitable for both armored and unarmored cables. For armored cables, the armor cone and clamping ring provide mechanical retention and electrical continuity.

3) What ingress protection rating does it offer?

When installed correctly with appropriate washers and shrouds, the gland can achieve IP65 or better, protecting against dust and water jets.

4) Which materials are available?

Standard construction is brass (often nickel-plated for corrosion resistance). Stainless steel versions may be available for highly corrosive environments.

5) What thread standards are offered?

Common options include ET, metric, and NPT threads to match panel or equipment entries. You should select the thread type based on your enclosure specification.

6) Is it certified for hazardous areas?

These glands are designed for flameproof and weatherproof use and are typically supplied with test approvals (e.g., CIMFR). Check the specific model certificate for your project documentation.