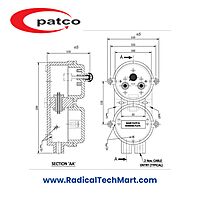

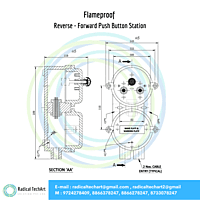

Patco FLP/WP Reverse - Forward Push Button Station

Patco FLP/WP Reverse–Forward Push Button Station – Ex-d, IP65

Heavy-duty flameproof and weatherproof reverse–forward–stop push button station with color-coded operators for safe motor control in Zone 1 & 2 hazardous areas, Gas Groups I, IIA, and IIB.

Download Now!!!

The Patco FLP/WP Reverse–Forward Push Button Station is a flameproof and weatherproof motor control station for hazardous process plants. It provides clear, color-coded reverse, forward, and stop functions and is certified for Zone 1 & 2 areas and Gas Groups I, IIA, and IIB.

Key Features

Ex-d explosion-protected control station as per IS/IEC 60079-1:2007

Suitable for Zone 1 & Zone 2 hazardous areas, Gas Groups I, IIA, IIB

High-pressure die-cast aluminium alloy LM6 enclosure

Epoxy polyester powder-coated finish for corrosion resistance

IP65 ingress protection – dustproof and water-jet resistant

Three push buttons rated 10A, 240V AC:

Green Forward – 1 NO contact

Yellow Reverse – 1 NO contact

Red Stop – mushroom head, pad-lockable with 1 NC contact

Internal and external earthing terminals for safety

Two M20 (3/4” ET) cable entries for easy field wiring

Stainless steel hardware for long service life in harsh environments

Technical Specifications (Table)

| Specification | Detail |

|---|---|

| Product Type | Flameproof/Weatherproof Reverse–Forward Push Button Station |

| Ex-Protection | Ex-d, IS/IEC 60079-1:2007 |

| Zone Classification | Zone 1 & Zone 2 |

| Gas Group | I, IIA, IIB |

| Ingress Protection | IP65 |

| Enclosure Material | High-pressure die-cast Aluminium Alloy LM6 |

| Surface Finish | Epoxy Polyester Powder Coating |

| Push Buttons | Green Forward (1 NO), Yellow Reverse (1 NO), Red Stop (1 NC mushroom) |

| Contact Rating | 10A, 240V AC (per push button) |

| Stop Button Type | Mushroom head, pad-lockable, 1 NC |

| Cable Entries | 2 × M20 (3/4" ET) |

| Earthing | Internal and external earthing terminals |

| Hardware | Stainless Steel |

| Application | Motor control in hazardous industrial plants |

Applications

Forward–reverse control of motors in hazardous areas

Chemical and petrochemical process plants

Refineries and gas handling facilities

Pharmaceutical solvent areas

Pump skids, agitators and conveyor drives in Zone 1 & 2 zones

Any industrial motor control where flameproof operation is required

What’s in the Box?

1 × Patco FLP/WP Reverse–Forward Push Button Station

Factory-fitted green, yellow and red push buttons with contacts

Earthing terminals inside enclosure

Cable entry plugs/reducers (as per OEM supply)

Mounting hardware (stainless steel—if supplied by OEM)

FAQ

1) Is this push button station suitable for explosive gas atmospheres?

Yes. It has Ex-d protection as per IS/IEC 60079-1:2007 and is suitable for Zone 1 & 2 areas for Gas Groups I, IIA, and IIB.

2) What are the contact configurations of the push buttons?

The green Forward and yellow Reverse buttons each have 1 NO contact, and the red mushroom Stop button has 1 NC contact.

3) Can the stop button be locked for maintenance?

Yes. The red stop button is a padlockable mushroom head for lockout during maintenance or emergency shutdown.

4) What is the ingress protection rating?

The enclosure is rated IP65, making it dust-tight and resistant to water jets, suitable for outdoor and washdown locations.

5) How many cable entries are provided?

Two M20 (3/4" ET) cable entries are provided for incoming and outgoing connections.

6) What is the enclosure material and finish?

The station is made from high-pressure die-cast aluminium alloy LM6 with an epoxy polyester powder-coated finish and stainless steel hardware.