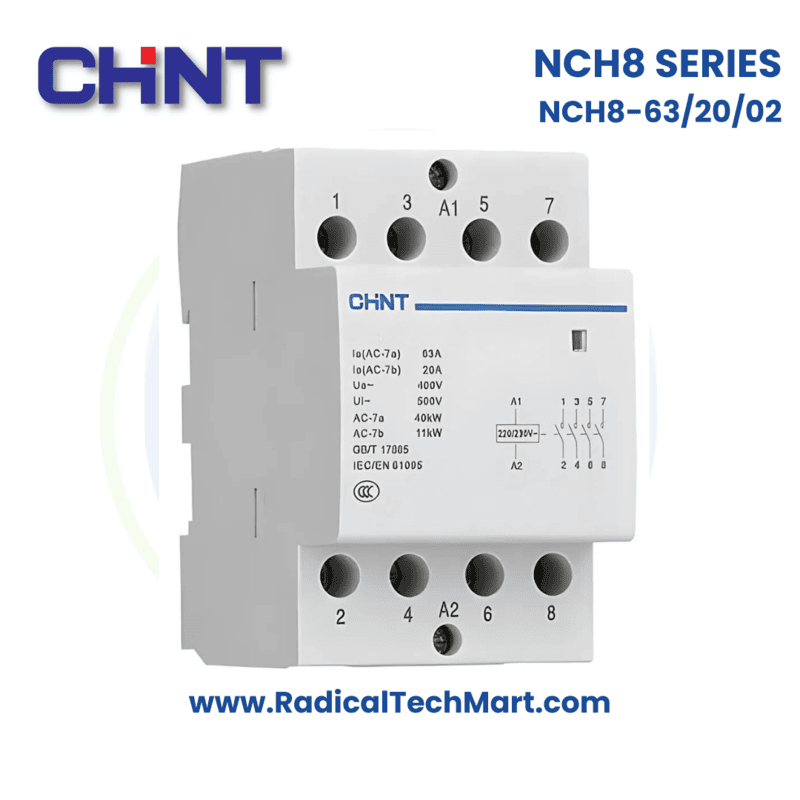

NCH8-63/20/02 Contactor

A. Product Overview

CHINT NCH8-63 is a DIN-rail modular AC contactor intended for remote switching and control of circuits in AC 50/60 Hz systems, with rated operating voltage up to 400 V and rated operating current up to 63 A (model dependent). It is commonly installed inside LV distribution boards, lighting control panels, AHU/utility panels, and standardized control enclosures where frequent switching is required without manual operation at the load end. The NCH8 series is designed for AC-1/AC-7a application categories (non-inductive or low-inductive load / resistance-type loads) and can be used for AC-7b (household motor loads) with derating.

B. Working Principle

The contactor uses an electromagnetic coil (A1/A2) to pull in a movable armature, closing the main contacts to energize the load circuit. When the coil supply is removed, the spring return opens the contacts, isolating the load. The specified coil operating window supports reliable pick-up and drop-out within defined voltage ranges, which is important in panels where control supply fluctuation occurs. Because it is a switching device (not a protective device), it is not designed to break short-circuit current and must be paired with an upstream short-circuit protective device such as an MCB/MCCB or fuse.

C. Key Applications

Oil & Gas: Lighting and utility feeders in shelters, non-critical auxiliary switching, package skids (with upstream SCPD)

Chemical & Process: Remote switching of resistive/low-inductive utility circuits, panelized auxiliaries

Power & Utilities: LT panel remote switching, lighting control, non-process auxiliary loads

Pharma: Clean utility panel switching, facility lighting groups, AHU auxiliaries (control-side switching)

Food & Beverage: Lighting groups, utility distribution switching, non-process auxiliaries

Water & Wastewater: Panel switching for lighting, dosing panel auxiliaries, small utility circuits

HVAC & Refrigeration: AHU/heater stages (resistive), ventilation and utility switching (as per load category)

Commercial/Infrastructure: Building lighting control, centralized switching via BMS/PLC outputs

D. Why Industries Use This Product

Plants use modular contactors to reduce manual switching dependency, standardize panel design, and enable automation/BMS/PLC control of electrical loads. In Indian industrial maintenance, this supports faster troubleshooting, easier spares planning, and predictable isolation of utility circuits during shutdowns. The key risk to manage is protection coordination: since the contactor is not meant to interrupt short-circuit currents, an upstream protective device is mandatory to prevent contact welding, arcing damage, and fire risk under fault conditions. Installation quality also matters—use copper conductors, follow tightening torque requirements, and avoid environments with inflammable/explosive gases or moist condensation to prevent insulation degradation and unreliable operation.

E. Suitable Buyers

OEMs: Panel builders integrating remote switching for lighting, heaters (resistive), and utility feeders in standard enclosures

EPC Contractors: LV panel packages for utilities/building services requiring modular DIN-rail switching

System Integrators: BMS/PLC-based load control where contactor coil is driven from control circuits

Maintenance & Utilities Teams: Commonly used for replacement in standardized lighting/utility control panels; preferred where quick swap DIN-rail devices are used in shutdown maintenance

Plant Engineering & Procurement: Widely accepted in retrofit projects for centralized switching and control, provided upstream short-circuit protection and load category suitability are ensured

Quick Answers

What is CHINT NCH8-63/20/02 Contactor?

It is a CHINT NCH8 series modular AC contactor (up to 63 A frame) used for remote switching/control of AC circuits in LV panels. It is a switching device and must be used with upstream short-circuit protection.

Where is CHINT NCH8-63 used?

Used in distribution boards and control panels for lighting control, utility feeders, HVAC auxiliaries, and other non-inductive/low-inductive loads across industrial and commercial installations.

Why is CHINT NCH8-63 required in industry?

It enables reliable remote ON/OFF control from PLC/BMS/control circuits, improves panel standardization, and supports safer operational switching—while protection is handled by dedicated MCB/MCCB/fuse upstream.

Who typically uses CHINT NCH8-63?

Panel OEMs, EPC contractors, system integrators, and plant maintenance/procurement teams for new panels, replacements, and retrofit centralized switching.

FAQ Section

1) Does the NCH8-63 contactor provide overload or short-circuit protection?

No. The NCH8 series is a control/switching device and is not designed to break short-circuit current. It must be used with a matching short-circuit protective device (MCB/MCCB/fuse) upstream, and overload protection should be provided as per the load and wiring design.

2) What load types is NCH8-63 intended to switch?

It is specified mainly for AC-1/AC-7a categories (non-inductive or low-inductive loads / resistive loads). It can be used for AC-7b (household motor loads) only with derating. For motor starting and higher inrush industrial loads, selection should be verified for duty and inrush suitability.

3) What does “/20” or “/02” typically indicate in NCH8 ordering?

In modular contactors, suffix codes generally refer to contact arrangement (for example, NO/NC combinations used for switching logic). For replacement procurement, matching the suffix to the existing panel wiring/terminal numbering is critical to avoid functional mismatch in control circuits.

4) What coil voltages and operating tolerance are supported?

The series supports common control coil voltages such as 24 V and 220/230 V (model dependent). The operating range guidance indicates pick-up typically within 85%–110% of the rated coil voltage and release within 20%–75%, which helps in panels with control supply variation.

5) What installation practices help avoid heating and failures?

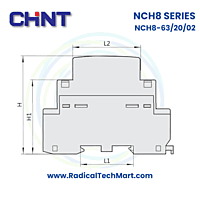

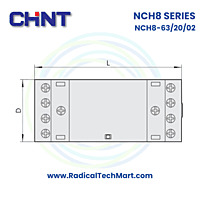

Install on TH35-7.5 DIN rail, use copper conductors only, and tighten terminals to the specified torque (notably higher torque for NCH8-63 terminals). Avoid installation in moist condensation or hazardous gas environments, and isolate power during installation/maintenance as specified.