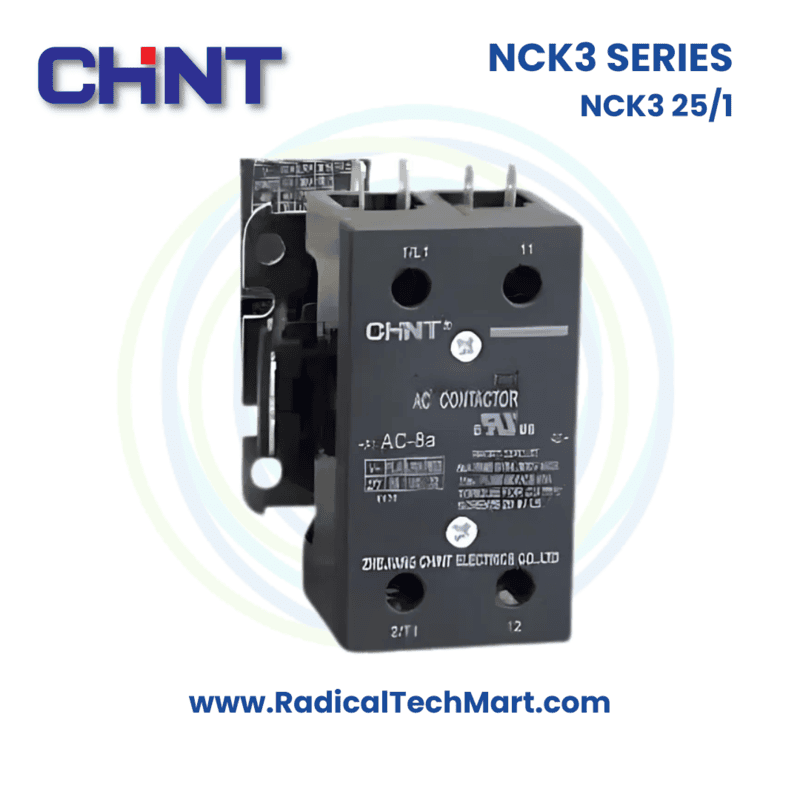

NCK3 32/1 Contactor

A. Product Overview

CHINT NCK3 series is a Definite Purpose Contactor range intended primarily for HVACR applications, where repetitive switching and motor-duty operation is common. The NCK3-32/1 variant is in the 32 A class (AC-8a utilization), with a typical configuration of 1-pole main contact arrangement for single-phase circuits (as coded by “/1” in the series designation). The catalog indicates the series supports UL, CE and CSA certifications, with rated insulation voltage up to 630 V and compliance to UL/CSA 60947-4-1 and IEC/EN 60947-4-1. This makes it suitable for standardized HVAC electrical packages where safety and code compliance are critical for commissioning and long-term maintenance.

B. Working Principle

The contactor operates using an electromagnetic coil to close/open the main power contacts. When control voltage is applied to the coil, the armature pulls in and closes the power contacts to energize the compressor or load circuit. Removing coil power releases the armature and opens the contacts, isolating the load. Coil specifications in the catalog show defined operating and drop-out voltage ranges, which helps ensure reliable pull-in and release in control panels where voltage fluctuations can occur due to long control wiring runs or transformer loading. As with all contactors, upstream short-circuit protection (fuse/MCB/MCCB) is required; the contactor is a switching device and not a fault-interruption protective device.

C. Key Applications (Bulleted)

Oil & Gas: HVAC package units in control rooms/shelters; AC plant compressors and condenser circuits

Chemical & Process: Utility HVAC/chiller compressor switching for control rooms and MCC buildings

Power & Utilities: Station HVAC and chiller plants for switchgear rooms and battery rooms

Pharma: AHU/chiller compressor control circuits supporting cleanroom utilities

Food & Beverage: Cold rooms, blast freezers, HVAC package units and refrigeration condensing units

Water & Wastewater: MCC/utility panels for HVAC and ventilation in pump houses and electrical rooms

HVAC & Refrigeration: Condensing units, chillers, rooftop units, packaged units, electric heaters (as per duty)

General Utilities: Centralized HVAC control panels and equipment OEM control boxes

D. Why Industries Use This Product

HVACR electrical systems depend on dependable motor switching to avoid compressor short-cycling, contact welding, nuisance shutdowns, and repeated breaker trips. A definite purpose contactor is selected to handle HVACR duty categories (including AC-8a as referenced for this series) and to match common OEM layouts and service practices. The NCK3 series also defines normal operating conditions such as pollution degree 2 and altitude up to 2000 m, supporting typical indoor panel environments. If an incorrect contact rating/coil voltage is used, or if terminations are loose/undersized, plants risk overheating at terminals, premature contact wear, coil burnout, and unplanned refrigeration downtime—often leading to product spoilage in cold storage, process shutdowns in pharma/chemicals, and HVAC failure in electrical rooms. The catalog provides conductor size ranges and tightening torque guidance for reliable installation, which is important for Indian service conditions where vibration and thermal cycling are common.

E. Suitable Buyers

OEMs: HVAC/chiller/condensing unit manufacturers using standardized definite purpose contactors for compressor and fan control

EPC Contractors: Utility HVAC electrical packages for industrial plants, buildings, and infrastructure projects

System Integrators: Chiller plant automation panels and BMS-integrated HVAC control enclosures

Maintenance & Utilities Teams: Commonly used for replacement in HVACR equipment where existing DPC form factor and coil voltage must match; preferred for serviceability and spares standardization

Plant Engineering & Procurement: Widely accepted in retrofit projects for HVACR panel refurbishment, especially where UL/CSA/IEC aligned equipment is required for compliance and reliability

Quick Answers

What is NCK3 32/1 Contactor?

It is a CHINT NCK3 series definite purpose contactor (HVACR duty), typically used for switching compressor or HVAC power circuits using an electromagnetic coil and main contacts, aligned to UL/CSA and IEC/EN 60947-4-1.

Where is NCK3 32/1 used?

Used in HVACR equipment and panels such as chillers, condensing units, rooftop units, cold storage systems, and utility HVAC distribution/control panels in industrial and commercial facilities.

Why is NCK3 32/1 required in industry?

It provides reliable remote switching for HVACR motor-duty circuits, supporting standardized maintenance and reducing downtime risk from frequent cycling and operational switching demands.

Who typically uses NCK3 32/1?

HVAC OEMs, refrigeration contractors, panel builders, utilities maintenance teams, and plant procurement/engineering teams for new equipment builds and replacement in standardized HVACR control circuits.

FAQ Section

1) What does “32/1” indicate in NCK3-32/1?

In the NCK3 series, “32” indicates the rated current class (AC-8a current rating for HVACR duty), and “/1” denotes the main contact arrangement code used for certain single-phase/control configurations. For replacement, matching the exact contact configuration and coil voltage used in the existing unit is critical.

2) Which standards and approvals does the NCK3 series align to?

The catalog states UL, CE and CSA certifications, and compliance to UL/CSA 60947-4-1 and IEC/EN 60947-4-1. This is relevant for HVACR OEM equipment and industrial facilities where electrical packages must align with recognized safety and performance standards.

3) What typical loads is a definite purpose contactor used for in HVACR?

It is commonly used for compressor switching, condenser fan circuits, electric heater stages, and packaged unit power control. Selection should be based on the application category and load duty (FLA/LRA expectations), and coordinated with upstream short-circuit protection and motor protection as required.

4) What coil/control voltages are available for NCK3 contactors?

The catalog lists multiple AC coil options commonly used in HVACR panels such as 24 V, 110/120 V, and 220/240 V (and higher voltages for some variants). Procurement should match the existing control transformer output and frequency (50/60 Hz) to avoid pull-in failures or overheating.

5) What installation practices reduce field failures in compressor control panels?

Use copper conductors within the specified cross-section range, tighten terminals to the recommended torque, and maintain installation within defined ambient and mounting conditions. Poor termination quality can cause heating and contactor failure, leading to HVAC shutdowns and repeated nuisance trips.